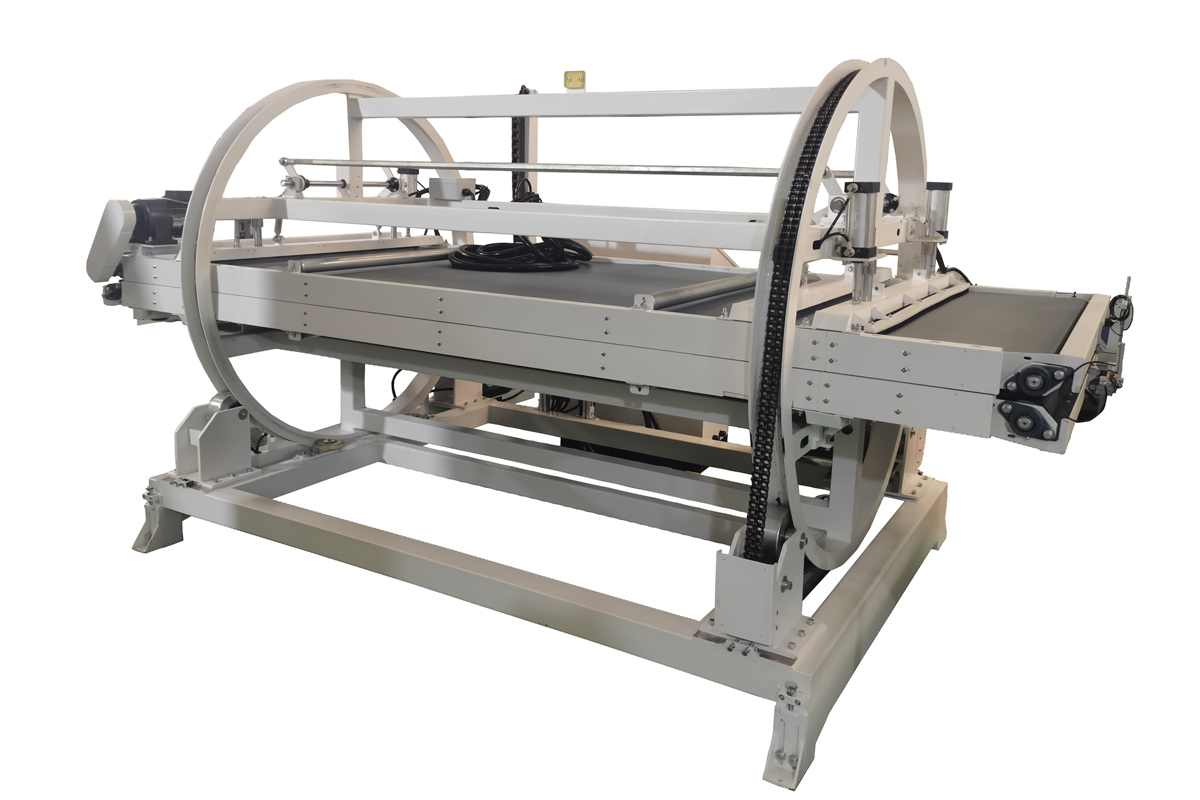

A Flipper Machine, also known as an Industrial Flipper Machine, is a specialized piece of mechanical equipment designed to meet the demands of object flipping in industrial production. By using motors, cylinders, or hydraulic systems to drive a flipping mechanism, the machine ensures stable gripping, controlled turning, and smooth releasing of objects. This automated flipping process improves productivity, reduces manual labor, and enhances workplace safety.

Core Components

Flipping Mechanism – Composed of arms, rotary axes, and support frames, responsible for executing the turning action.

Driving System – Includes electric motors, pneumatic cylinders, or hydraulic pumps to provide sufficient power for flipping.

Control System – Equipped with PLC or microcontroller systems for accurate and automated flipping control.

Safety Devices – Limit switches, emergency stop buttons, and protective guards to ensure safe operation.

The Industrial Flipper Machine is widely applied in multiple fields:

Steel Industry – Flipping steel plates, coils, and heavy materials with improved efficiency and reduced risks.

Automotive Manufacturing – Turning car bodies, chassis, and components for assembly, welding, and inspection.

Food Processing – Flipping raw materials or semi-finished products for automated production.

Logistics & Warehousing – Handling and turning goods, crates, and boxes for easier stacking, loading, and transport.

Aerospace Industry – Precision flipping of aircraft parts, shells, and other high-tech components.

Product Features and Advantages

High Efficiency – Rapid and accurate flipping operations increase overall productivity.

Stability & Durability – Built with high-quality steel and advanced welding for long service life.

Enhanced Safety – Safety sensors and emergency stop features protect operators.

Customizable Design – Tailored to meet specific flipping requirements such as weight, size, and angle.

Automation & Intelligence – Optional smart features like automatic positioning and programmable flipping sequences.

Maintenance and Troubleshooting

To maintain long-term stable performance, the following steps are recommended:

Regular Inspection – Check fasteners, lubrication, and electrical systems.

Cleaning – Remove dust and debris to keep the machine clean.

Lubrication – Replace lubricants periodically to ensure smooth mechanical operation.

Electrical Check – Inspect cables and wiring for wear or damage.

Fault Handling – Stop the machine immediately if abnormalities occur and seek professional service.

FAQ

Q1: What is a Flipper Machine?

A Flipper Machine is industrial equipment used to flip objects to specific angles for assembly, inspection, and packaging.

Q2: How does a Flipper Machine work?

It uses motors, cylinders, or hydraulic systems to power a flipping mechanism, ensuring secure gripping, controlled turning, and safe release.

Q3: What types of Flipper Machines exist?

They can be categorized by flip angle (90°, 180°, 360°), drive mode (electric, pneumatic, hydraulic), or structural form (fixed, mobile).

Q4: What industries use Flipper Machines?

Steel, automotive, food processing, aerospace, logistics, and warehousing industries.

Q5: What are the benefits of using an Industrial Flipper Machine?

Increased efficiency, reduced manual labor, improved safety, and customized flipping solutions.

Q6: How should a Flipper Machine be maintained?

Perform routine inspections, lubrication, electrical checks, and cleaning to ensure stable operation.

Q7: What should be done if a failure occurs?

Shut down the machine, cut off the power, and contact professional technicians.

Q8: What is the future trend of Flipper Machines?

They are moving toward automation, intelligent control, and modular designs for higher efficiency and easier maintenance.