Our self-developed MCM Soft Porcelain Production Line is an efficient and customized production system that can be flexibly adjusted according to the specific needs of customers, providing one-stop solutions from equipment to production process. In addition to equipment, we also provide production formulas, production process guidance, and assist customers to complete the layout optimization of the production line to ensure smooth production.

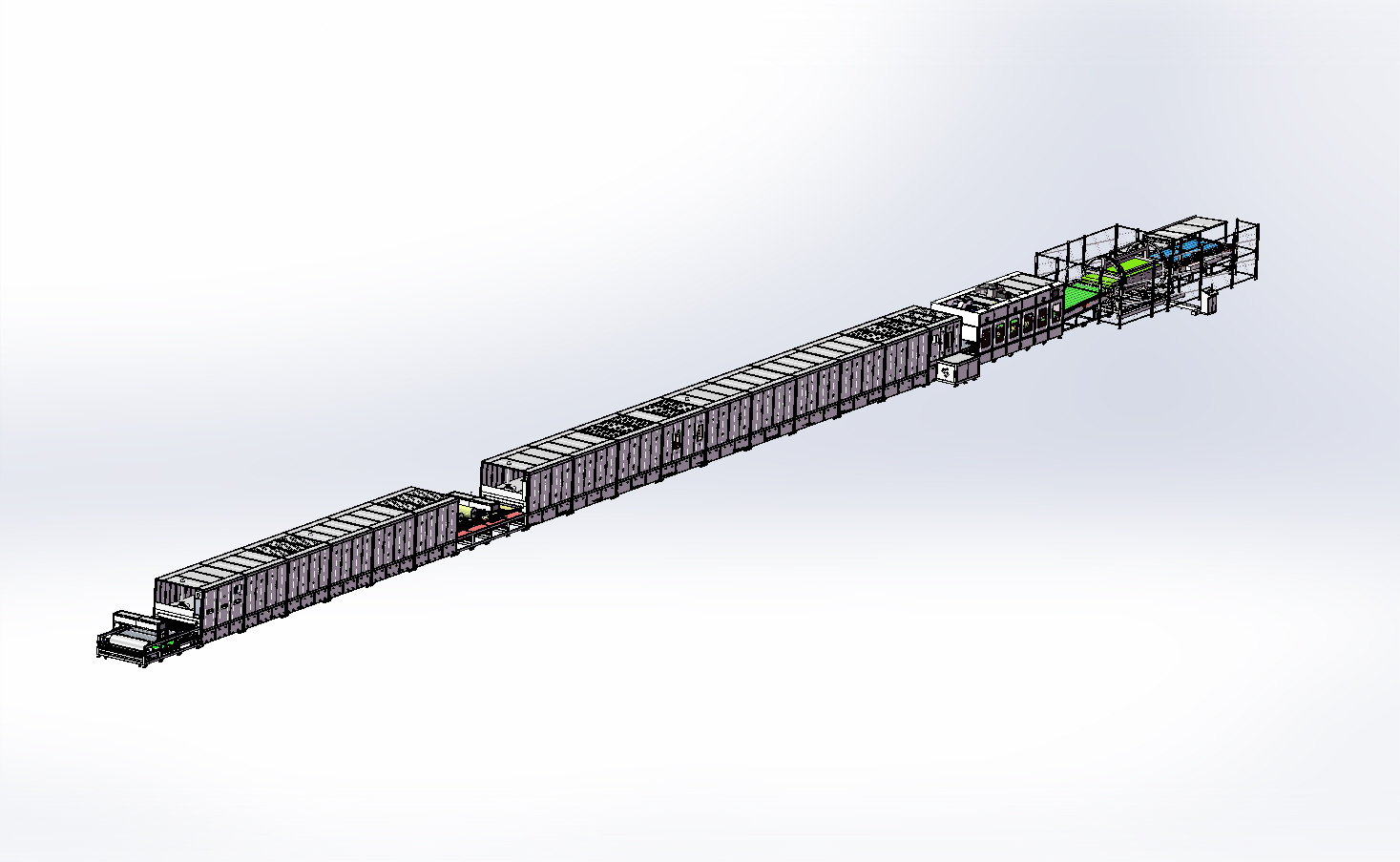

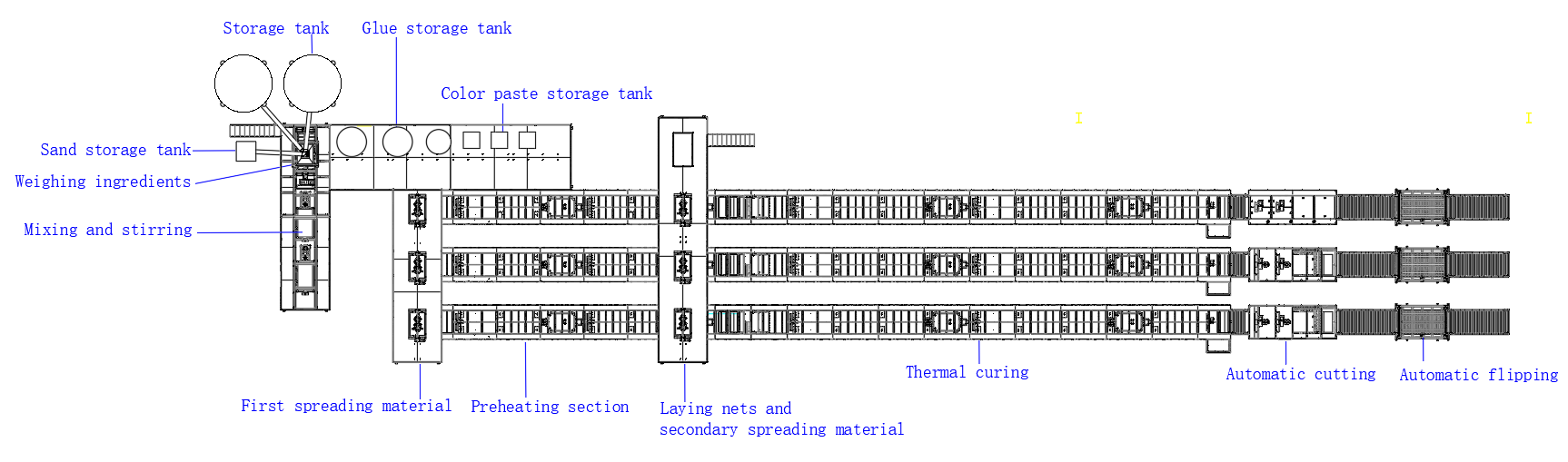

Our MCM Soft Porcelain Production Line integrates advanced automation technology, including a complete set of production equipment such as production batching system, automatic coating and molding system, baking and curing system and automated slitting system, which is capable of realizing high-efficiency full-process automated production. The daily output of the whole production line is 800~1000 square meters, which is suitable for large-scale and continuous production to meet the production needs of customers of different scales.

Main System Introduction

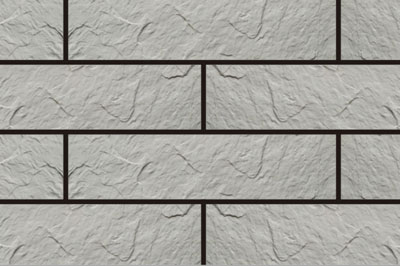

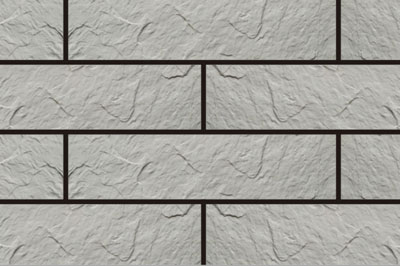

Pave Method Options of MCM Soft Porcelain

High-efficiency capacity and customization

Each production line has a daily capacity of 800~1000 square meters, which is particularly suitable for mass production needs. We are not only able to customize the production line according to customers' requirements, but also provide personalized customization services according to different product specifications, colors and patterns to meet the diversified needs of customers in product development and market expansion.

Technical support and production line layout optimization

As a technology pioneer in MCM soft porcelain industry, our company not only provides a full set of equipment solutions, but also provides customers with comprehensive technical support, including production formula, production process customization and development. Our technical team will assist in completing the installation and commissioning of the entire production line according to the actual situation of the customer, and provide detailed production training and technical guidance to ensure that the customer can run the production line smoothly.

Automation and Intelligent Advantage

Our MCM Soft Porcelain Production Line realizes the automatic operation of the whole process from raw material batching, molding to slitting through the automation control system, which reduces the manual intervention and improves the production efficiency. Meanwhile, the intelligent production equipment can monitor the production data in real time to ensure the stability of product quality and significantly reduce the production cost and scrap rate.

What is MCM soft porcelain production line?

MCM soft porcelain production line is a system of equipment specially desicgned for the production of MCM (Modified Clay Material) soft porcelain, an environmentally friendly, lightweight and flexible building material widely used in architectural decoration

What are the main components of MCM soft porcelain production line?

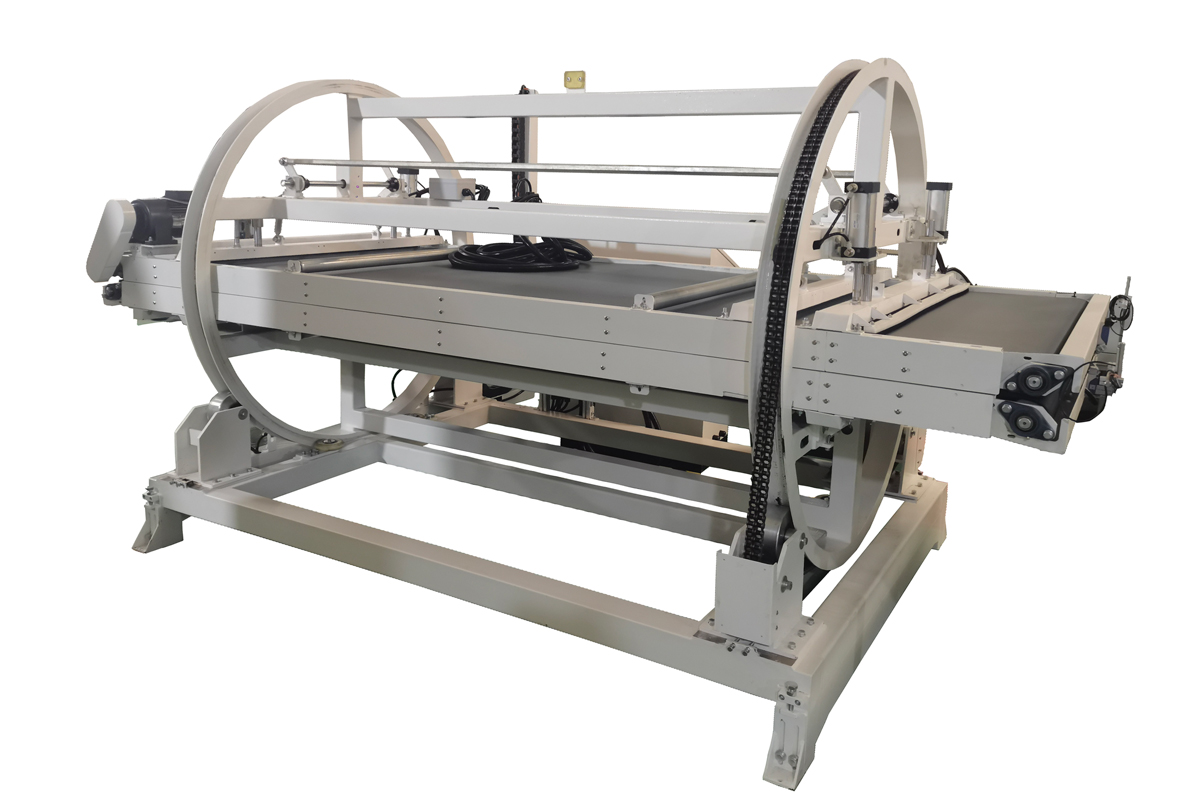

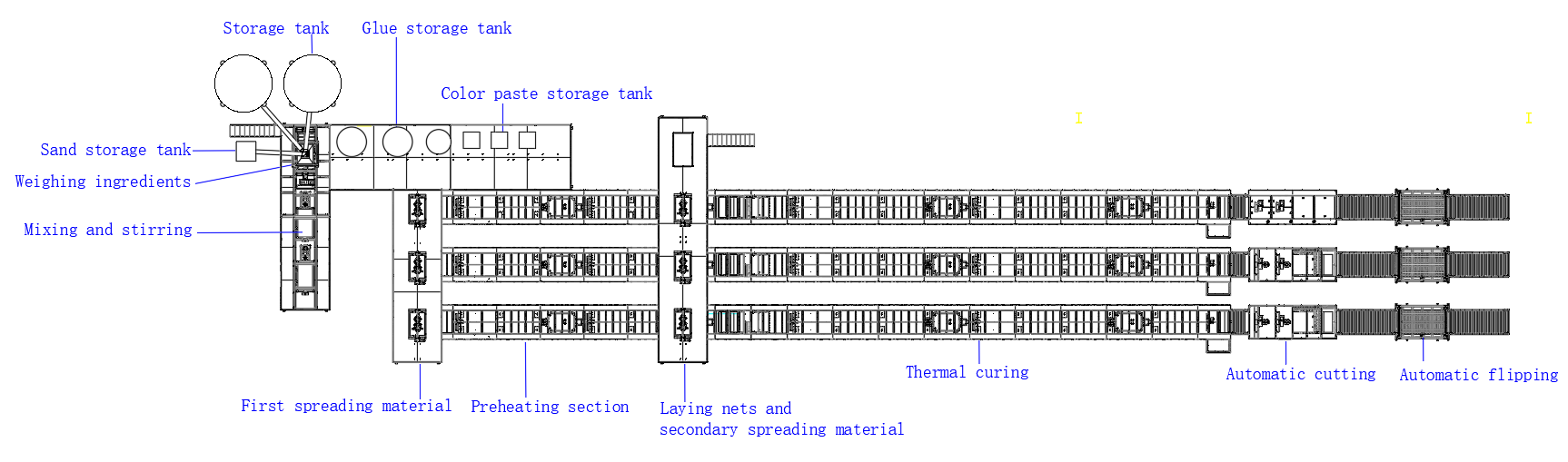

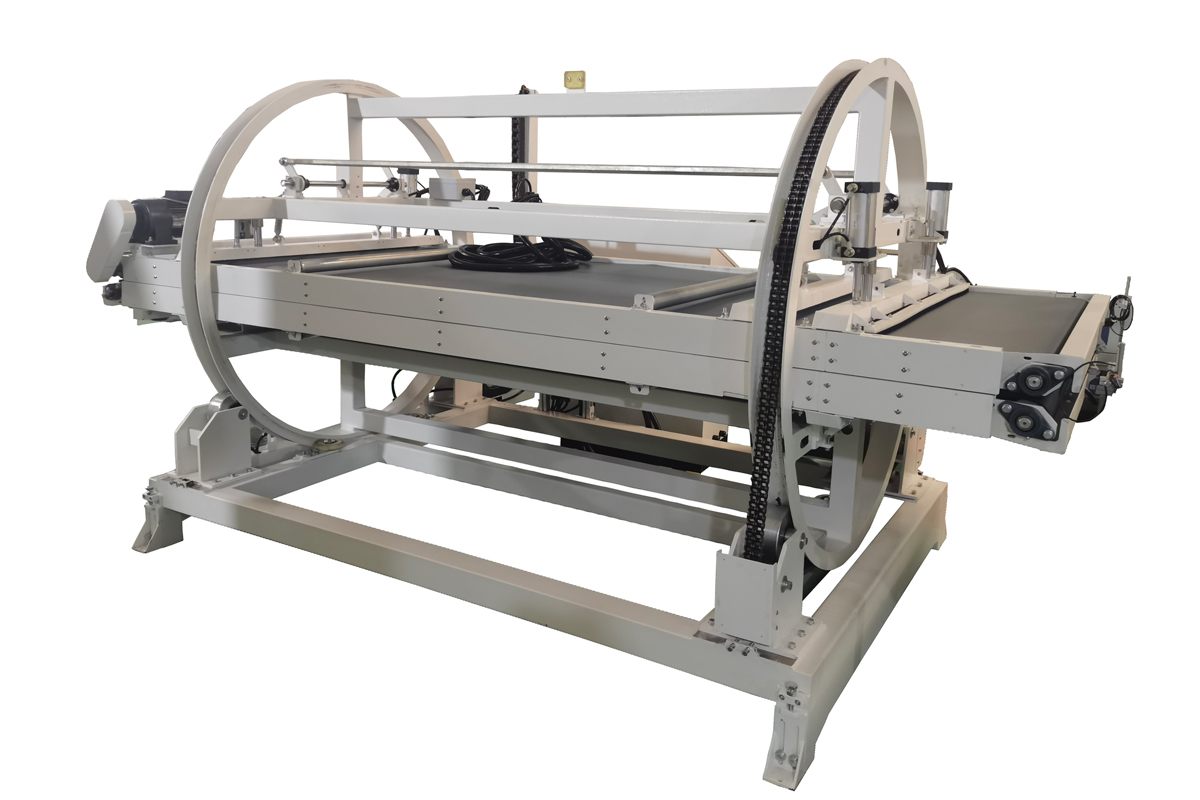

The main components include raw material mixer , raw material dispenser, Forming mould, Tunnel furnace baking equipment, automatic cuting machine, packaging equipment and control system.

What is the production process of MCM soft porcelain production line?

The production process usually includes weighing ingredients, mixing and stirring, First spreading material, Preheating, Laying nets and secondary spreading material, Bake curing,cutting, surface treatment and final packaging and warehousing.

What is the production capacity of MCM soft porcelain production Line?

Depending on the configuration of the line, a large number of MCM soft porcelain can be produced per hour, depending on the specifcations of the equipment and the level of automation, The production line of Boan has a high capacity, and each line can produce 800 to 1000 square meters of small bricks per day.

What are the benefits of MCM soft porcelain?

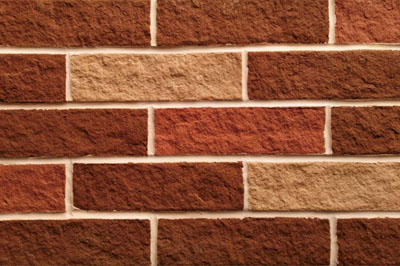

MCM soft porcelain material is a new type of environmental protection building decoration material, with light weight, good flexibility, acid and alkali resistance, frost resistance, earthquake resistance, crack resistance, high strength, fire, waterproof, appearance and shape of various features, widely used in building exterior wall, interior, road decoration. In terms of building exterior walls, MCM soft porcelain materials can replace traditional stone, ceramics and other materials, with lighter, thinner and stronger characteristics, which can reduce the weight of the building and improve the seismic performance of the building. At the same time, MCM soft porcelain materials also have a rich choice of colors and textures, which can meet different architectural styles and design needs. In interior decoration, MCM soft porcelain materials can be used for wall, floor, ceiling and other parts of the decoration, can create a rich variety of effects, such as imitation wood grain, imitation stone grain, imitation metal grain, etc., make the interior space more beautiful and fashionable. In addition, MCM soft porcelain materials can also be used to make partition walls, with sound insulation, heat insulation, fire prevention and other functions, can improve the comfort and safety of the building. In short, MCM soft porcelain building applications can provide buildings with lightweight, high-strength, beautiful, durable decorative materials to meet different architectural design and construction needs.

How does the of MCM soft porcelain production Line perform in terms of energy consumption?

MCM soft porcelain production Line are usualy equipped with energy-saving tunnel ovens and highly efficient automation equipment, which reduces energy consumptionand overall production costs through intelligent temperature control systems.

How to maintain MCM soft porcelain production line?

Equipment such as mixers, spreading machine, tunnel ovens and cutting machine need to be regularly inspected and maintained to maintain cleanliness, and vulnerable parts should be replaced in a timely manner to ensure efficient operation of the production line

What is the installation and commissioning process of MCM soft porcelain production line?

Installation and debugging personnel should receive professional training, be familiar with the installation process and technical requirements of the equipment, strictly follow the installation and debugging guide of the equipment to complete the installation and debugging of the equipment, check the performance indicators of the equipment after installation, and only use it after meeting the requirements

What is theinvestment of MCM soft porcelain production line?

In market demand is stable, especially in the field of green building and environmental protection decoration, investing in an eficientMCM soft porcelain production line can recover the cost in a relatively short time, and at the same time gain considerable profits.