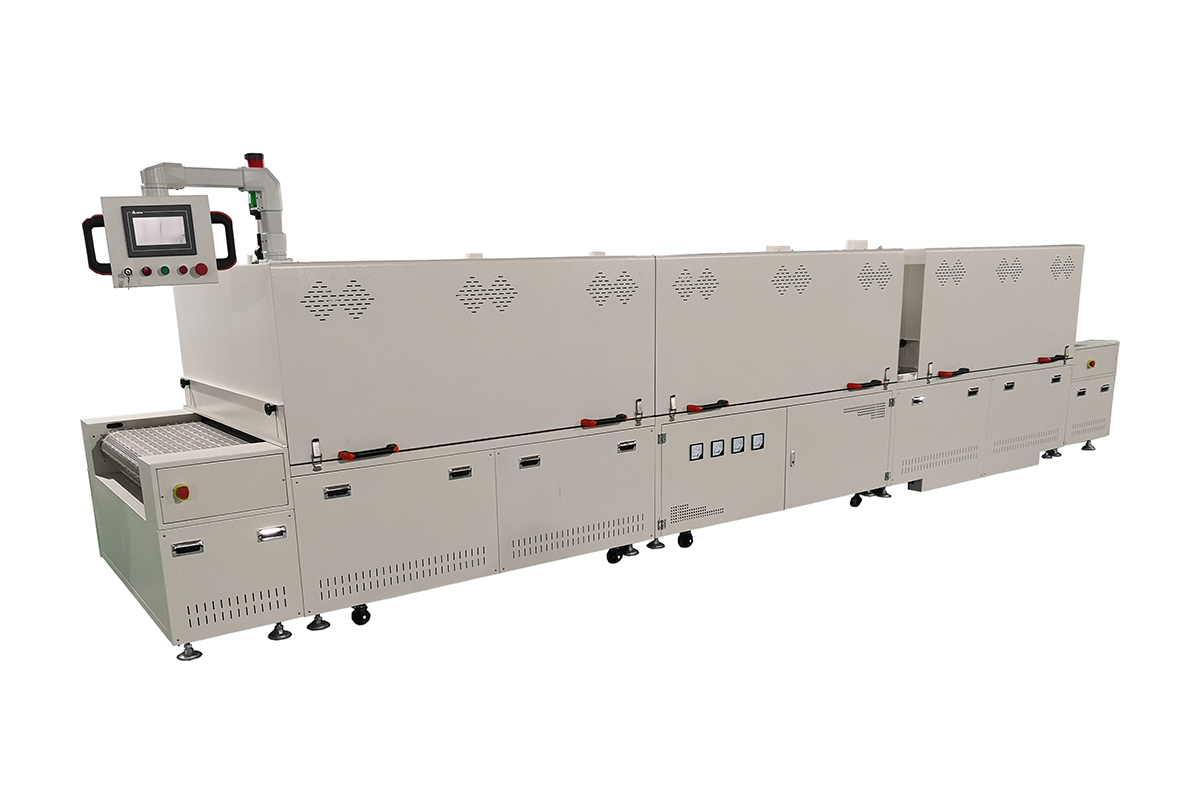

Hot air circulating Tunnel Furnaces are advanced thermal processing equipment widely used in various industries, including manufacturing, food processing, and electronics. These furnaces utilize a continuous flow of hot air to achieve uniform heating and drying of products, ensuring high-quality results in a cost-effective manner.

Working Principle

The primary function of a hot air circulating Tunnel Furnace is to create a controlled environment where hot air is circulated around the materials being processed. The furnace typically consists of a long, insulated tunnel where products move through on a conveyor system. Heated air is blown into the tunnel and circulated by fans, ensuring consistent temperature distribution throughout the chamber.

Main features

1. High-efficiency heating: adopting hot air circulation technology, the heating speed is fast and the thermal efficiency is high, which can significantly improve the production efficiency.

2. Uniform temperature: the temperature inside the furnace is uniformly distributed to ensure the uniformity of material heating, avoiding the deformation of materials or quality problems caused by uneven temperature.

3. Energy saving and environmental protection: the hot air circulating Tunnel Furnace adopts highly efficient heat recovery system, which can significantly reduce energy consumption, and at the same time reduce the exhaust emissions, in line with environmental requirements.

4. Easy to operate: the equipment is easy to operate, easy to control, according to the needs of different materials to adjust the temperature and time and other parameters.

5. Wide range of application: it is suitable for heating and drying materials of various shapes, sizes and materials, such as metal parts, plastic products, chemical raw materials and so on.

Parameters

| Inner size H*W*D | Very standard customization |

| Temperature range | Room temperature +20~200℃ |

| Temperature control precision | ±1.0℃ |

| Temperature uniformity | ±1.5% (empty furnace test) |

| Power supply | Three-phase 380V |

Structural composition

Hot air circulation tunnel furnace is mainly composed of the following parts:

1. Furnace body: composed of heat insulation material and metal shell, with good heat preservation performance.

2. Hot air generator: generates high temperature air to provide heat source for the furnace.

3. Hot air circulation system: including fan, air duct, dampers and other components, responsible for circulating the high temperature air in the furnace body.

4. Temperature control system: accurately control the temperature inside the furnace through temperature sensors and controllers to ensure the stability and reliability of the heating process.

5. Conveying system: It is used to feed materials into and out of the furnace to realize continuous production.

Key Features

1.Uniform Heating: The design of the furnace allows for even distribution of heat, minimizing temperature fluctuations and ensuring that all products are processed uniformly.

2.Energy Efficiency: Hot Air Circulating Tunnel Furnaces are designed to optimize energy use, often featuring advanced insulation and heat recovery systems that reduce overall energy consumption.

3.Adjustable Temperature Control: These furnaces allow for precise temperature settings, enabling operators to customize heating profiles according to specific product requirements.

4.Versatility: Suitable for a wide range of applications, including baking, drying, curing, and sterilizing various materials, from food products to industrial components.

5.Automation: Many models incorporate automated controls for temperature, airflow, and conveyor speed, enhancing operational efficiency and reducing the need for manual intervention.

Applications

1.Food Industry: Used for drying fruits, vegetables, and other food products, ensuring moisture content is reduced to desired levels while preserving flavor and nutritional value.

2.Manufacturing: Ideal for curing paints and coatings on metal and plastic parts, ensuring even application and durability.

3.Pharmaceuticals: Employed in the drying process of various medications and formulations, maintaining stringent quality standards.

4.Electronics: Used for drying printed circuit boards and components after soldering processes.

FAQ

What is a Hot Air Circulating Tunnel Furnace?

A Hot Air Circulating Tunnel Furnace is a thermal processing device that uses circulating hot air to achieve uniform heating and drying of products, widely used in industries such as food processing, manufacturing, and electronics.

What is the working principle of a Hot Air Circulating Tunnel Furnace?

The furnace consists of a long, insulated tunnel where products are transported on a conveyor belt while heated air is blown in and circulated by fans, ensuring even temperature distribution throughout the chamber.

What are the main features of a Hot Air Circulating Tunnel Furnace?

Key features include uniform heating, energy efficiency, adjustable temperature control, versatility in applications, and automation capabilities.

What are the applications of Hot Air Circulating Tunnel Furnaces?

They are commonly used for drying fruits and vegetables in the food industry, curing paints and coatings in manufacturing, drying medications in pharmaceuticals, and drying printed circuit boards in electronics.

What advantages does a Hot Air Circulating Tunnel Furnace have over traditional ovens?

Compared to traditional ovens, these furnaces offer higher heating uniformity, faster processing speeds, and improved energy efficiency.

How is temperature control achieved in a Hot Air Circulating Tunnel Furnace?

Many models are equipped with precise temperature control systems that allow operators to adjust heating temperatures based on specific product requirements.

What is the energy efficiency of Hot Air Circulating Tunnel Furnaces?

These furnaces are designed with advanced insulation and heat recovery systems, significantly reducing overall energy consumption and enhancing energy efficiency.

Is cleaning and maintenance of a Hot Air Circulating Tunnel Furnace difficult?

Cleaning and maintenance are generally straightforward; regular checks and cleaning of fans, heating elements, and conveyor belts can ensure efficient operation.

How do you choose the right Hot Air Circulating Tunnel Furnace?

When selecting a furnace, consider product type, processing capacity, required temperature range, and specific application needs to ensure the equipment meets production demands.

What automation features do Hot Air Circulating Tunnel Furnaces have?

Automation features include automatic control of temperature, airflow, and conveyor speed, enhancing operational efficiency and reducing the need for manual intervention.